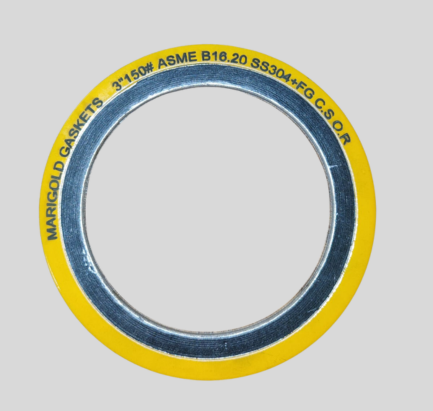

In modern industrial operations, effective sealing solutions are essential for safety, efficiency, and uninterrupted performance. Among the wide range of industrial gaskets available today, spiral wound gaskets are regarded as one of the most reliable sealing products for high-pressure and high-temperature applications. If you are searching for a trusted spiral wound gasket manufacturer in India, Marigold Gaskets is a name you can rely on for quality, precision, and long-term performance.

This blog provides a detailed overview of spiral wound gaskets, their construction, advantages, applications, materials, standards, and why Marigold Gaskets is a preferred choice for customers across India and international markets.

What Is a Spiral Wound Gasket?

A spiral wound gasket is a semi-metallic gasket made by spirally winding a preformed metal strip and a soft filler material together. This unique construction combines the strength and resilience of metal with the sealing capability of soft fillers, resulting in excellent performance under extreme operating conditions.

Spiral wound gaskets are commonly used in:

- High-pressure pipelines

- Heat exchangers

- Boilers

- Pressure vessels

- Valves and flanged joints

- Petrochemical and refinery equipment

Due to their flexible structure, spiral wound gaskets can adapt to flange surface irregularities and maintain a tight seal even during pressure and temperature fluctuations.

Why Spiral Wound Gaskets Are Widely Used in Industry

Spiral wound gaskets are one of the most popular sealing solutions across industries because of their superior performance and durability.

1. Excellent Sealing Performance

The combination of metal windings and filler material ensures high compression recovery and leak-free sealing, even in critical applications.

2. High Temperature and Pressure Resistance

These gaskets are designed to withstand extreme temperatures and pressures, making them suitable for demanding industrial environments.

3. Long Service Life

Spiral wound gaskets offer excellent resistance to creep, relaxation, and mechanical stress, resulting in extended service life.

4. Resistance to Thermal Cycling

They perform reliably under frequent heating and cooling cycles without loss of sealing integrity.

5. Versatile Material Options

A wide range of metal and filler materials makes spiral wound gaskets compatible with various fluids and gases.

Materials Used in Spiral Wound Gaskets

As a leading spiral wound gasket manufacturer in India, Marigold Gaskets manufactures products using high-quality raw materials that comply with international standards.

Metal Materials

- Stainless Steel (SS 304, SS 316, SS 321, SS 347)

- Carbon Steel

- Alloy Steel

- Monel

- Inconel

- Hastelloy

Filler Materials

- Flexible Graphite

- PTFE (Tefl on)

- Mica

- Ceramic fillers

The correct selection of materials ensures chemical compatibility, pressure resistance, and optimal sealing performance for specific applications.

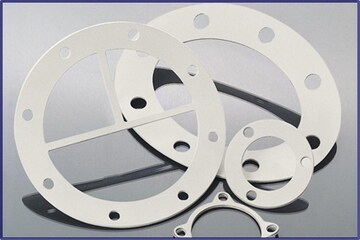

Types of Spiral Wound Gaskets Manufactured by Marigold Gaskets

Marigold Gaskets offers a complete range of spiral wound gaskets to meet diverse industrial requirements.

Spiral Wound Gasket – Type W (Without Rings)

Used in tongue-and-groove or male-and-female flange arrangements where compression is controlled.

Spiral Wound Gasket with Outer Ring – Type WO

The outer guide ring ensures proper gasket alignment and prevents over-compression during installation.

Spiral Wound Gasket with Inner Ring – Type IW

The inner ring prevents inward buckling of the gasket and protects it from aggressive process media.

Spiral Wound Gasket with Inner and Outer Ring – Type IWO

Recommended for high-pressure, high-temperature, and critical service applications.

All spiral wound gaskets are manufactured in accordance with ASME B16.20, DIN, BS, and other international standards.

Applications of Spiral Wound Gaskets

Spiral wound gaskets manufactured by Marigold Gaskets are widely used in multiple industries, including:

- Oil and Gas Industry

- Petrochemical and Refinery Plants

- Power Generation Plants

- Chemical Processing Industry

- Fertilizer Industry

- Pharmaceutical Industry

- Pulp and Paper Industry

- Marine and Offshore Applications

Their ability to perform under extreme conditions makes them an essential sealing solution for critical industrial operations.

Why Choose Marigold Gaskets as Your Spiral Wound Gasket Manufacturer in India?

Choosing the right gasket manufacturer is crucial for ensuring plant safety and operational efficiency. Marigold Gaskets has earned a strong reputation as a reliable spiral wound gasket manufacturer in India by consistently delivering high-quality products and customer-focused solutions.

1. Advanced Manufacturing Facilities

Marigold Gaskets uses modern machinery, precision winding equipment, and strict process controls to manufacture gaskets with consistent quality.

2. International Standards Compliance

All products are manufactured and inspected as per ASME, DIN, BS, and other globally recognized standards.

3. Customization and Engineering Support

We offer customized spiral wound gaskets based on:

- Flange size and pressure class

- Operating temperature and pressure

- Process media

- Customer drawings and specifications

4. Competitive Pricing

As an Indian manufacturer, Marigold Gaskets provides cost-effective solutions without compromising on quality or performance.

5. On-Time Delivery

Efficient production planning and supply chain management ensure timely delivery for both domestic and export orders.

6. Technical Expertise

Our experienced team supports customers in selecting the right gasket design and materials for maximum sealing reliability.

Quality Assurance and Testing

Quality is a key focus at Marigold Gaskets. Every spiral wound gasket undergoes stringent quality checks, including:

- Dimensional inspection

- Visual examination

- Material traceability

- Compression and recovery testing

These quality control measures ensure reliable performance and consistent sealing results in real-world applications.

Environmental and Safety Benefits

High-quality spiral wound gaskets play a vital role in reducing leakage and fugitive emissions. Marigold Gaskets’ products help:

- Improve plant safety

- Minimize environmental impact

- Reduce maintenance costs

- Enhance overall operational efficiency

By delivering reliable sealing solutions, we support safe and sustainable industrial operations.

Conclusion

If you are looking for a dependable and experienced spiral wound gasket manufacturer in India, Marigold Gaskets is your trusted partner. With advanced manufacturing capabilities, strict quality control, customized solutions, and competitive pricing, we deliver spiral wound gaskets that meet the most demanding industrial requirements.

Whether your application involves high pressure, extreme temperatures, or aggressive chemicals, Marigold Gaskets provides sealing solutions you can rely on for long-term, leak-proof performance.

Contact Marigold Gaskets today to discuss your spiral wound gasket requirements and experience precision-engineered sealing solutions.