The industrial world depends on high-quality sealing solutions — and at the heart of many critical applications lies the humble but powerful spiral wound gasket. If you operate in sectors such as petrochemicals, oil & gas, power plants, chemical processing, or heavy fabrication, you already know that the choice of gasket can make or break your installation’s performance. That’s where trusted Spiral Wound Gasket Manufacturers in Ahmedabad like Marigold Gaskets come into play.

In this blog, we will explore:

- What are spiral wound gaskets?

- Why choose spiral wound gaskets?

- Why Ahmedabad is a hub for gasket manufacturing

- An introduction to Marigold Gaskets

- How to choose the right gasket manufacturer

- Applications of spiral wound gaskets

- FAQs about spiral wound gaskets

Whether you’re a procurement engineer, plant manager, or industrial buyer — this comprehensive guide is your one-stop resource.

What Are Spiral Wound Gaskets?

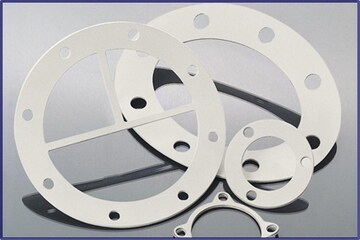

A spiral wound gasket is a high-performance industrial sealing solution made by winding alternating layers of metal and filler materials. The metal component (often stainless steel) provides structural strength and recovery, while the filler (such as graphite or PTFE) ensures compressibility and sealing efficiency.

These gaskets are specially designed to withstand:

- High temperatures

- High pressures

- Chemical corrosion

- Thermal cycling

- Mechanical stress

That makes them ideal for use in critical flanged connections in pipelines, pressure vessels, heat exchangers, and valves.

Key Features:

✔ Excellent sealing under fluctuating temperatures

✔ High mechanical strength

✔ Durable and long-lasting

✔ Resistant to chemicals and corrosion

✔ Suitable for high-pressure applications

Why Spiral Wound Gaskets Are Preferred Industrial Seals

Spiral wound gaskets have become the go-to solution for industries requiring maximum reliability.

1. Performance in Extreme Conditions

Unlike traditional flat gaskets, spiral wound gaskets maintain sealing integrity even under fluctuating thermal and pressure loads. This makes them ideal for:

- Steam lines

- Cryogenic systems

- Petrochemical processing

- High-speed rotating equipment

2. Versatility of Material Options

Manufacturers like Marigold Gaskets offer spiral wound gaskets in multiple materials, such as:

- SS304, SS316L, Inconel, Monel windings

- Graphite, PTFE, ceramic fillers

- Outer rings for accurate flange centering

This flexibility ensures the perfect match for every industrial application.

3. Long-Lasting & Low-Maintenance

Spiral wound gaskets are engineered for durability. Their robust design allows the gasket to relax and recover under pressure, which means fewer shutdowns and reduced maintenance costs.

Ahmedabad – The Industrial Hub for Gasket Manufacturing

Ahmedabad has emerged as a thriving center for industrial manufacturing in India. Its strategic location, strong infrastructure, and industrial ecosystem make it a preferred choice for buyers seeking quality products at competitive prices.

Why Ahmedabad for Gaskets?

✔ High-end engineering expertise

✔ Well-established MSME sector

✔ Proximity to major ports and customers

✔ Competitive pricing due to local material supply

Among the many manufacturers in the city, Marigold Gaskets stands out as a leader in delivering world-class spiral wound gaskets that meet international standards.

Introducing Marigold Gaskets – Top Spiral Wound Gasket Manufacturers in Ahmedabad

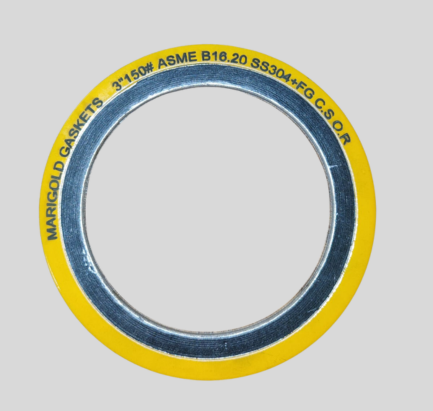

Marigold Gaskets has carved a niche in the gasket industry by focusing on innovation, quality, and reliability. As a reputed manufacturer based in Ahmedabad, Marigold offers a wide range of spiral wound gaskets tailored for demanding industrial environments.

What Makes Marigold Gaskets Different?

✨ Customized Solutions: Every plant is different — Marigold understands this. They offer tailor-made spiral wound gaskets designed to meet unique specifications, flange standards, and operating environments.

✨ Strict Quality Control: Each gasket undergoes rigorous testing to ensure compliance with API, ASME, DIN, and other international standards.

✨ Wide Material Range: Whether you need stainless steel windings or PTFE fillers, Marigold’s material options suit diverse applications.

✨ Timely Deliveries: With a strong supply chain network and local presence in Ahmedabad, they ensure consistent delivery schedules.

✨ Competitive Pricing: Locally sourced materials and efficient manufacturing help Marigold offer cost-effective solutions without compromising quality.

How to Choose the Right Spiral Wound Gasket Manufacturers in Ahmedabad

Selecting the best

Spiral Wound Gasket Manufacturers in Ahmedabad r is as important as choosing the right gasket type. Here’s what you should look for:

1. Engineering Expertise

A manufacturer should not only make products but also provide technical support — helping you choose the right gasket based on fluid media, temperature, and pressure requirements.

2. Certified Quality Standards

Ensure your supplier follows industry benchmarks such as:

- ASME B16.20

- API 601

- DIN standards

This guarantees product performance and safety.

3. Material Traceability

Quality gaskets require quality materials. A good manufacturer maintains a traceability record for all raw materials used.

4. After-Sales Service

Post-purchase support, installation guidance, and replacement advice are invaluable, especially in critical applications.

Marigold Gaskets meets all these criteria — making them one of the most trusted Spiral Wound Gasket Manufacturers in Ahmedabad.

Applications of Spiral Wound Gaskets

Spiral wound gaskets are used across a broad range of industries. Let’s explore the most common applications.

1. Petrochemical Plants

Sealing pipelines and reactors in refineries requires gaskets that can withstand harsh chemicals and high temperatures — spiral wound gaskets are ideal.

2. Oil & Gas Sector

From offshore platforms to onshore drilling facilities, these gaskets ensure safe sealing even under high pressures.

3. Power Generation

Steam lines and heat exchangers in thermal power stations rely on spiral wound gaskets for leak-free performance.

4. Chemical Processing

Aggressive chemicals demand corrosion resistance — available through various filler materials like PTFE and graphite.

5. Shipbuilding & Marine

Marine environments require corrosion resistance and durability against saltwater — which makes spiral wound gaskets suitable.

6. Aerospace & Defense

High-precision applications require custom gasket solutions designed and manufactured with strict quality adherence.

Maintenance Tips for Spiral Wound Gaskets

To maximize the lifespan of your gaskets, follow these best practices:

✔ Ensure proper flange alignment

✔ Use correct torque sequence and rating

✔ Inspect flange surfaces before installation

✔ Replace gaskets during scheduled shutdowns

✔ Avoid over-compression

Proper installation and maintenance not only improve sealing performance but also reduce unplanned downtime — saving your business time and money.

FAQs – Spiral Wound Gaskets

Q1: What materials are used in spiral wound gaskets?

Spiral wound gaskets typically use combinations of stainless steel (like SS304, SS316) and fillers like graphite, PTFE, or ceramic.

Q2: What industries use spiral wound gaskets?

They are widely used in petrochemical, oil & gas, power plants, chemical processing, shipbuilding, and heavy fabrication industries.

Q3: Are spiral wound gaskets reusable?

Generally, spiral wound gaskets are designed for single use. Reuse can compromise sealing integrity.

Q4: Why choose a local Spiral Wound Gasket Manufacturers in Ahmedabad ?

Local manufacturers Spiral Wound Gasket Manufacturers in Ahmedabad – Marigold gaskets offer quicker delivery, competitive pricing, easier communication, and custom solutions.

Conclusion

When it comes to high-performance sealing solutions, spiral wound gaskets are the gold standard — especially in industries where safety and efficiency are critical. For businesses looking for dependable products, choosing the right manufacturer is essential.

If you’re searching for Spiral Wound Gasket Manufacturers in Ahmedabad, Marigold Gaskets stands out as a trusted and quality-driven partner. With expert engineering, high standards, and customized sealing solutions — they deliver the performance your projects demand.

if you want to know more about spiral wound gaskets click here