Spiral wound gaskets are among the most trusted and widely used sealing solutions in industrial piping systems. From oil refineries to chemical plants and power stations, these gaskets are chosen where high pressure, high temperature, and critical sealing performance are required.

In this in-depth guide, you’ll learn what spiral wound gaskets are, how they work, their types, applications, advantages, materials, and how to select the right spiral wound gasket for your industry. This article is written to help both engineers and procurement teams make informed decisions while being fully SEO-optimized for industrial search intent.

What Is a Spiral Wound Gasket?

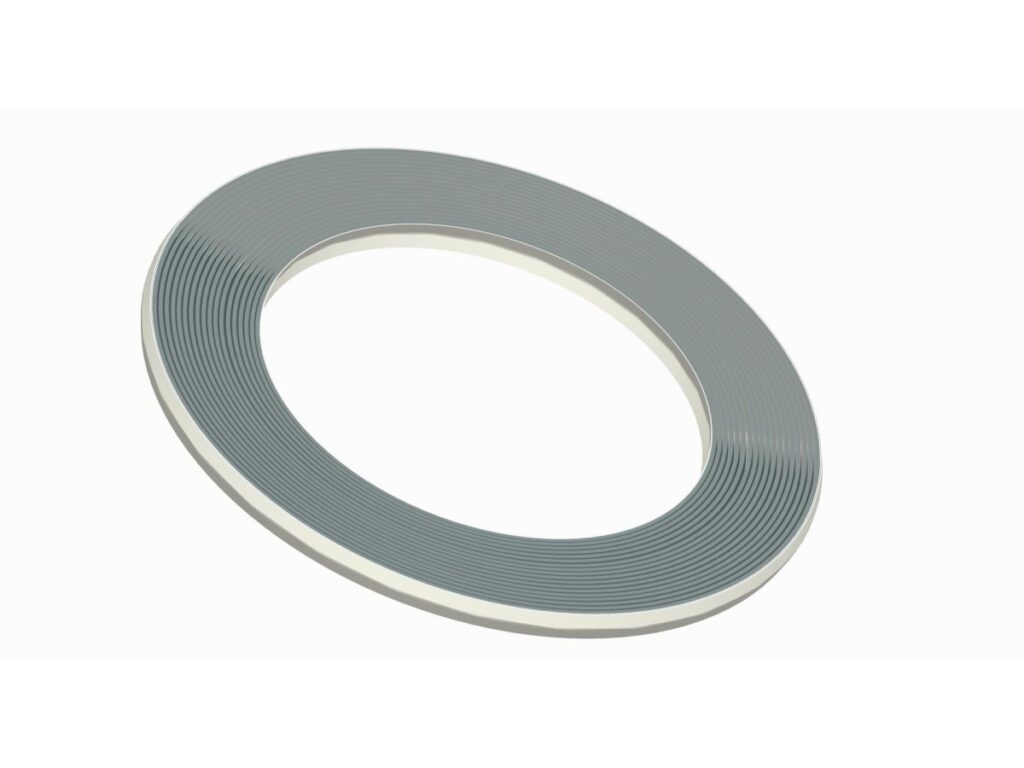

A spiral wound gasket is a semi-metallic gasket constructed by winding alternating layers of metal strip and soft filler material into a spiral form. This unique structure combines the strength of metal with the sealing efficiency of soft materials.

The metal strip provides mechanical strength and resilience, while the filler material fills microscopic flange irregularities, ensuring a leak-proof seal even under extreme operating conditions.

Spiral wound gaskets are commonly used in raised face (RF) and tongue-and-groove flanges, especially where conventional gaskets fail due to pressure or temperature fluctuations.

How Spiral Wound Gaskets Work

The working principle of spiral wound gaskets is based on controlled compression.

When the gasket is compressed between two flanges:

- The metal windings act like a spring, maintaining sealing stress

- The soft filler material flows into flange imperfections

- The gasket adapts to thermal expansion and pressure variations

This flexibility makes spiral wound gaskets ideal for dynamic operating environments, where vibration, pressure cycling, or temperature changes are common.

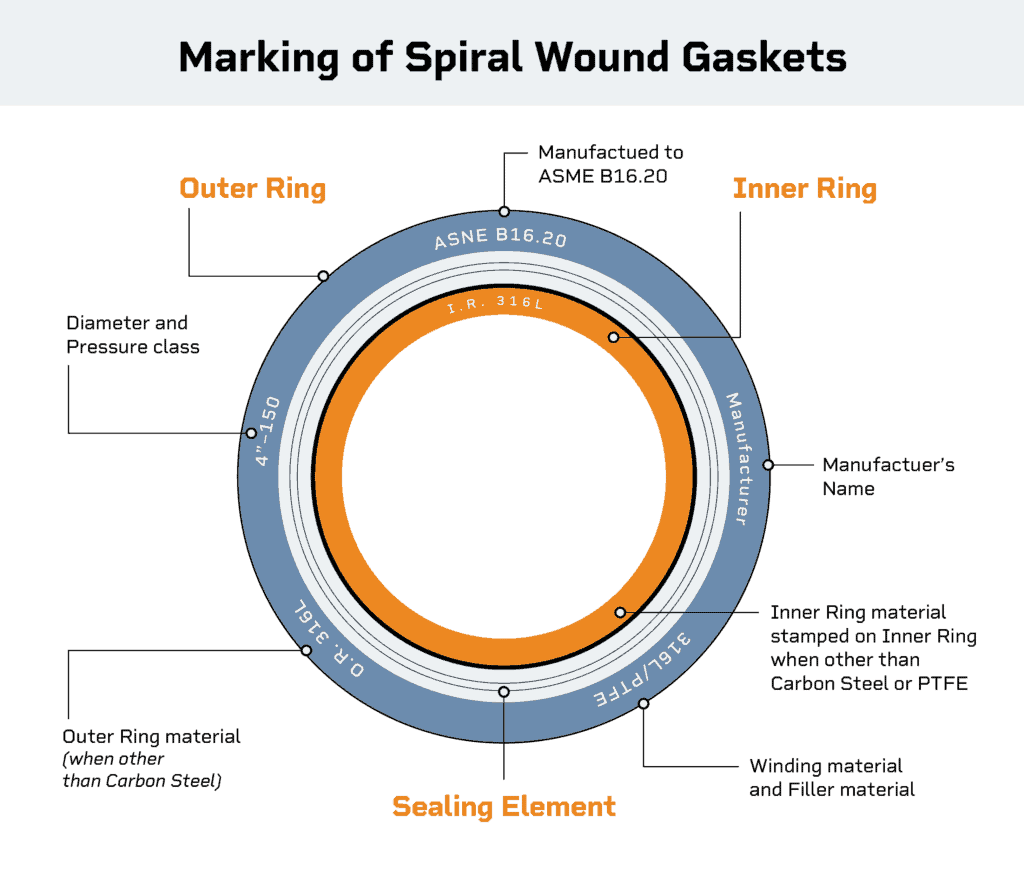

Key Components of a Spiral Wound Gasket

1. Metal Winding

Common metals include:

- Stainless Steel (SS 304, SS 316, SS 321)

- Carbon Steel

- Monel

- Inconel

- Hastelloy

The metal provides strength, elasticity, and corrosion resistance.

2. Filler Material

The filler ensures tight sealing. Popular options include:

- Graphite (most common)

- PTFE

- Mica

Graphite-filled spiral wound gaskets are preferred for high-temperature and high-pressure applications.

3. Outer Ring (Guide Ring)

The outer ring:

- Centers the gasket correctly

- Prevents over-compression

- Improves gasket stability

4. Inner Ring (Optional)

Inner rings are used in high-pressure applications to:

- Prevent inward buckling

- Protect the gasket from media erosion

- Improve longevity

Types of Spiral Wound Gaskets

4

1. Spiral Wound Gasket Without Ring

- Used in tongue-and-groove or male-female flanges

- Requires precise installation

- Not recommended for inexperienced handling

2. Spiral Wound Gasket with Outer Ring

- Most commonly used type

- Ideal for raised face flanges

- Prevents over-compression

3. Spiral Wound Gasket with Inner & Outer Ring

- Designed for high-pressure and high-temperature services

- Prevents gasket blowout

- Extends service life in critical applications

Common Applications of Spiral Wound Gaskets

Spiral wound gaskets are used across multiple industries due to their versatility:

Oil & Gas Industry

- Refineries

- Offshore platforms

- Pipelines

- Heat exchangers

Chemical & Petrochemical Plants

- Reactors

- Distillation columns

- High-pressure vessels

Power Generation

- Boilers

- Steam lines

- Turbines

Pharmaceuticals

- Clean steam systems

- Process piping

Marine & Shipbuilding

- Engine rooms

- Fuel systems

- High-pressure valves

Advantages of Spiral Wound Gaskets

Spiral wound gaskets offer several technical advantages over non-metallic and solid metal gaskets:

- Excellent sealing under extreme pressure

- High temperature resistance

- Recovery after thermal cycling

- Resistance to vibration and shock

- Long service life

- Wide material compatibility

- Compliance with international standards

These benefits make them the preferred choice for critical flange joints.

Temperature and Pressure Capabilities

The performance of a spiral wound gasket depends on its material combination.

- Graphite filler: up to 450°C (higher in inert environments)

- PTFE filler: up to 260°C

- Pressure range: suitable for Class 150 to Class 2500 flanges

Always consult gasket specifications and flange ratings before selection.

Spiral Wound Gaskets vs Other Gasket Types

| Feature | Spiral Wound | Ring Type Joint | Non-Metallic |

| Pressure Handling | Excellent | Excellent | Limited |

| Temperature Range | Wide | Very Wide | Limited |

| Recovery | High | Low | Moderate |

| Installation Tolerance | Medium | Low | High |

Spiral wound gaskets strike the best balance between strength and flexibility, which is why they dominate industrial sealing applications.

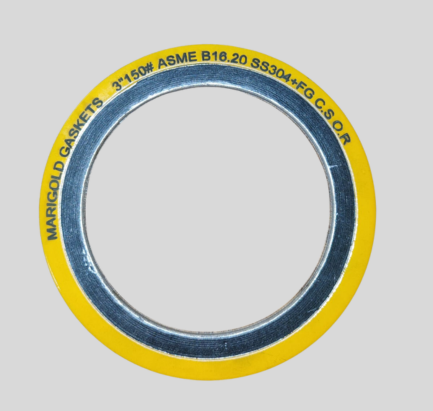

Standards and Specifications

Spiral wound gaskets are manufactured according to international standards such as:

- ASME B16.20

- DIN standards

- EN standards

Using standard-compliant gaskets ensures safety, reliability, and compatibility across systems.

How to Choose the Right Spiral Wound Gasket

Before selecting a spiral wound gasket, consider:

- Operating temperature

- System pressure

- Media compatibility

- Flange type and size

- Industry standards

- Required service life

Choosing the wrong gasket can result in leaks, downtime, or safety hazards.

Installation Best Practices

Even the best gasket can fail if installed incorrectly.

- Ensure flange surfaces are clean and aligned

- Use proper bolt tightening sequence

- Apply uniform torque

- Avoid over-compression

- Use calibrated torque tools

Correct installation significantly improves gasket performance and lifespan.

Final Thoughts

Spiral wound gaskets are a critical component in industrial sealing systems, offering unmatched reliability in harsh operating conditions. Their unique design, material flexibility, and compliance with global standards make them indispensable in modern industries.

If your operations demand high safety, durability, and performance, spiral wound gaskets are not just an option — they are a necessity.